Effectivity is the secret in electric vehicle design and may have an effect on automobile vary and vitality prices. For a given machine know-how, there received’t be a lot effectivity benefit from one producer versus one other in apples-to-apples product comparability. Nonetheless, there may be one other manner to consider effectivity, and that’s by way of operational and purposeful effectivity. That’s, trying past a tool’s inherent effectivity and contemplating how and when it’s operated. That is the place “good” management options come into play and is especially relevant to electrified auxiliaries, which depend on the management of unbiased electrical motors to drive auxiliaries similar to pumps and compressors fairly than being mechanically pushed by a combustion engine.

Sensible options function units “on-demand,” which matches the output vitality provided with the precise vitality demand based mostly on the loading situations or desired operation. This method reduces vitality consumption and audible noise by shutting the machine off when not in operation or working at a decreased or extra environment friendly working level.

This moreover reduces tools put on and tear, thus extending operational lifetime or decreasing upkeep necessities. General, good options can impression day-to-day contributions to elevated automobile vary, operator consolation, and complete value of possession.

Power-efficient and on-demand good management options could be achieved in a number of methods. This text will concentrate on good answer methods for effectively controlling auxiliaries similar to pumps and compressors and a number of the options of the KEB T6 Auxiliary Inverter system. The T6 is a high-voltage inverter system that helps as much as 6 unbiased AC motor management outputs with modular energy choices (7.5kW, 15kW, or 30kW) for every output.

Superior Motor Controls

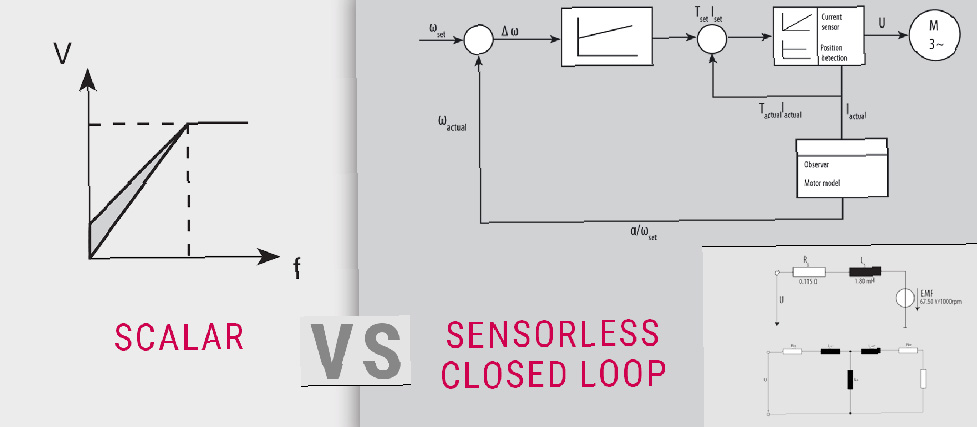

Motor management strategies decide how a motor is operated and depend on an inverter’s management algorithms to manage the output energy to the motor. Thus, totally different management strategies can affect a motor’s operational effectivity. There are two major management strategies for AC motors, scalar, and vector management.

Scalar Management

Scalar management is often known as volts-per-hertz control and is an open-loop management kind. Right here, the inverter outputs a hard and fast voltage output for a given frequency equivalent to a command pace based mostly on a Volts/Hertz curve from a motor’s rated working level. For the reason that output voltage is set by the pace command fairly than the precise energy necessities of the load, scalar management operation could be much less environment friendly below partial masses. Scalar management additionally tends to have comparatively poor efficiency since there isn’t a pace or torque management and restricted torque out there at low speeds. Scalar management may be very fundamental and solely applies to asynchronous induction motors. It’s outlined right here to supply context to the advantages of vector management options.

Vector Management

A extra superior answer is vector management, often known as field-oriented management. The sort of management is a closed loop that makes use of suggestions from the motor. With vector management, there may be unbiased management of each torque and pace. Moreover, the voltage output is optimized based mostly on a vector calculation and operates extra effectively in response to the precise load necessities.

Closed-loop systems additionally present much better pace regulation and torque management, permitting for a high-performance response. That is significantly relevant when implementing on-demand auxiliary controls options that preserve vitality by dynamically adjusting motor pace or switching techniques off/on in response to an auxiliary machine’s instantaneous or conditional energy necessities.

Vector management can be utilized with asynchronous induction motors for elevated operational effectivity and efficiency. In distinction, synchronous motors similar to everlasting magnet servo motors require closed-loop suggestions of the rotor place to modulate the stator electromagnetic subject angle. Encoder suggestions and sensorless management algorithms have two forms of strategies for closing the loop.

Encoder vs. Sensorless Suggestions

The normal technique used an encoder mounted on the motor shaft for pace and/or place suggestions. The downsides are that the encoder and the cabling are further system parts that add value, take up house, and are potential factors of failure or prone to electrical interference.

As an alternative of encoder suggestions, sensorless control algorithms make the most of an observer motor mannequin based mostly on the motor traits and the precise measured motor present and voltage as suggestions to shut the loop. This eliminates the necessity for encoder {hardware} whereas offering comparable efficiency below most circumstances. Sensorless fashions have limitations at very low steady working speeds (<1% motor-rated pace) and wouldn’t be really helpful for traction or holding purposes however are in any other case ideally fitted to use with pumps and compressors.

When contemplating sensorless management, it needs to be famous that just some producers’ sensorless algorithms are equal. Though a comparability could also be tough to quantify, the important traits embody the pace management response and the torque management accuracy.

Moreover, the simplicity of setup needs to be thought-about. KEB has been a pacesetter in sensorless management improvement and efficiency for over 15 years, with intensive expertise in pump and compressor purposes throughout varied energy ranges and industries. Moreover, the setup of sensorless management has been simplified with an automatic motor study process to characterize motors (solely fundamental motor nameplate information is required).

Embedded Management Options

Electrifying auxiliaries present new alternatives for the way these techniques could be managed. Past the motor management itself, good options may make the most of revolutionary embedded management options.

Such options are sometimes energy on-demand management packages. These are used to regulate the motor based mostly on the specified operation of the auxiliary and may keep in mind a number of different components throughout the automobile to find out the optimum setpoint from an energy-efficiency or efficiency standpoint. This may be in distinction to a combustion engine-driven auxiliary, which might rely on engine pace. As an alternative, electrified auxiliaries could be managed independently and intelligently exactly HOW and WHEN they’re wanted.

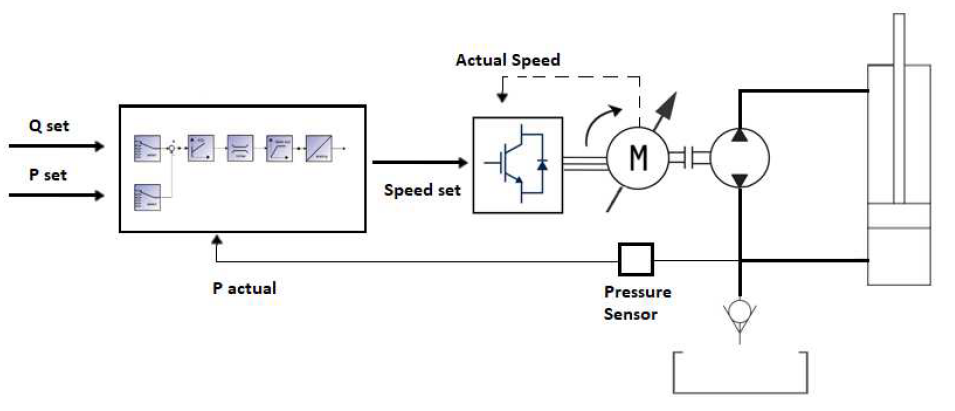

Energy on-demand management packages can vary from fundamental on/off management to dynamic efficiency and much more superior algorithms which use refined fashions of the auxiliary system and inputs from the automobile to calculate the motor management setpoints.

As a use case instance, an influence steering pump can be an software that might readily profit from good energy on-demand management options.

Historically, an influence steering pump pushed by an engine would always produce strain and circulation. The strain is dissipated by reduction valves as wasted vitality when not absolutely utilized. An electrified auxiliary can as an alternative use condition-based management packages to scale back vitality consumption.

- A fundamental implementation can be to function the pump motor at a decreased idle pace when the steering isn’t in-use, based mostly on the steering angle sensor pace.

- A extra superior implementation could calculate baseline working factors for various pace ranges for the reason that circulation and strain necessities range drastically based mostly on automobile pace.

- Much more superior options may use a hydraulic strain sensor and (sensorless) motor pace suggestions in PI management loops to extra dynamically and exactly management the required motor pace and torque based mostly on the precise demand necessities.

The T6 Auxiliary Inverter accommodates an embedded controller for straightforward integration of good management packages. This enables system integration builders and auxiliary techniques suppliers to implement their product know-how into customized, value-added performance with ready-to-use good software program management options for his or her clients.