Battery cyclers play an essential role throughout the development of batteries and therefore, are considered an indispensable part of any battery testing laboratory or manufacturing facility.

Join this presentation at next week’s Virtual Conference on EV Engineering, presented by Bitrode, where we will first discuss the requirements for an advanced battery cycler to meet the current and future demands of the fast-growing battery industry. We will then introduce Bitrode Digital Cycler (BTDCTM), the next generation of battery cyclers designed and developed in close collaboration with professionals in the battery industry for the purpose of streamlining and expediting various stages of battery development.

Other sessions at our Spring Virtual Conference include:

Drive Performance Through Battery Cell Chemistry

The demand for safer, longer-lasting, faster charging, cheaper and energy-dense batteries is disrupting the entire industry. Rapid battery evolution, affordability, sustainability and recyclability are key to delivering the next generation of EVs. The automotive and transportation sector is transforming their fleets to electric cars, electric buses, and electric trucks. Auto OEMs, start-ups, battery makers and specialty chemical companies are all investing large amounts of resources for groundbreaking innovations. Time is of the essence and accelerating innovation is key.

Launching and managing a battery innovation program presents a unique set of challenges due to the rapidly shifting consumer expectations, evolving public energy options and of course, the amazing advances that are happening at what seems like an almost daily pace. Coupled with that is an acute need to source scientific talent that is well versed in both the language of battery development and the specific contours associated with the wider transportation sector that is driving battery development.

This webinar, presented by Dassault Systemes, will cover case studies on design, optimization and innovation of battery chemistry, as well as design-for-manufacturing approaches.

Webinar highlights:

• Virtual twin of battery cell and simulation of cell performance

• Validated use-cases covering challenges, solutions and results

• Driving battery innovation programs from ideation through to delivery

• Engagement framework with our Customers to drive performance of cell for the next generation

Other sessions at our Spring Virtual Conference include:

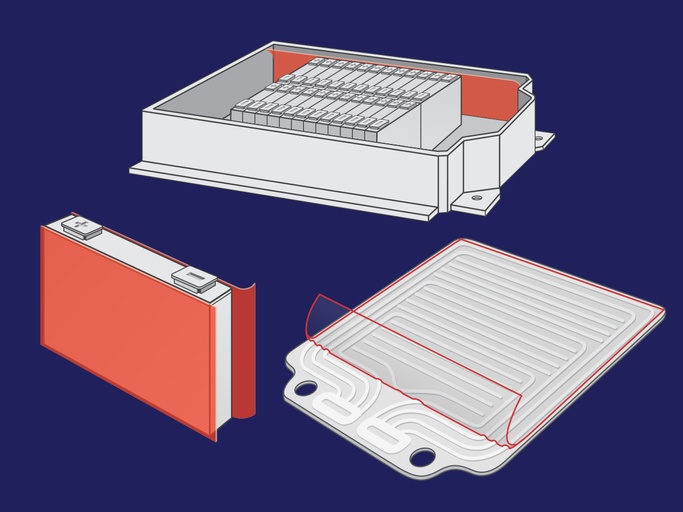

Choosing The Right Tape When Designing for Electrical Insulation in EV Batteries

Choosing a dielectric protection barrier during the design and construction of EV battery modules and packs is a critical engineering decision. With an optimized solution, engineers can maximize pack energy density, improve vehicle reliability, and enhance consumer safety.

In this session, presented by Max VanRapporst and Scott Kruskinski of Avery Dennison Performance Tapes, we will discuss the comparative advantages of using pressure-sensitive adhesive tapes versus coatings to create dielectric barriers. He’ll explain how to choose a specific dielectric tape based on the application, including pack electrical insulation, cell wrapping, cooling plates, and insulation around flexible busbars. He’ll also discuss how proper tape selection can help maximize scale-up and large-volume production. Finally, Max will highlight some of the potential pitfalls and failure modes that can occur when the wrong dielectric protection barriers are chosen.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 17 – 20, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.