Measuring battery health and safety continuously is an important challenge—lithium-ion batteries can experience several challenges over their lifetimes such as unintended capacity loss, short circuits and thermal runaway.

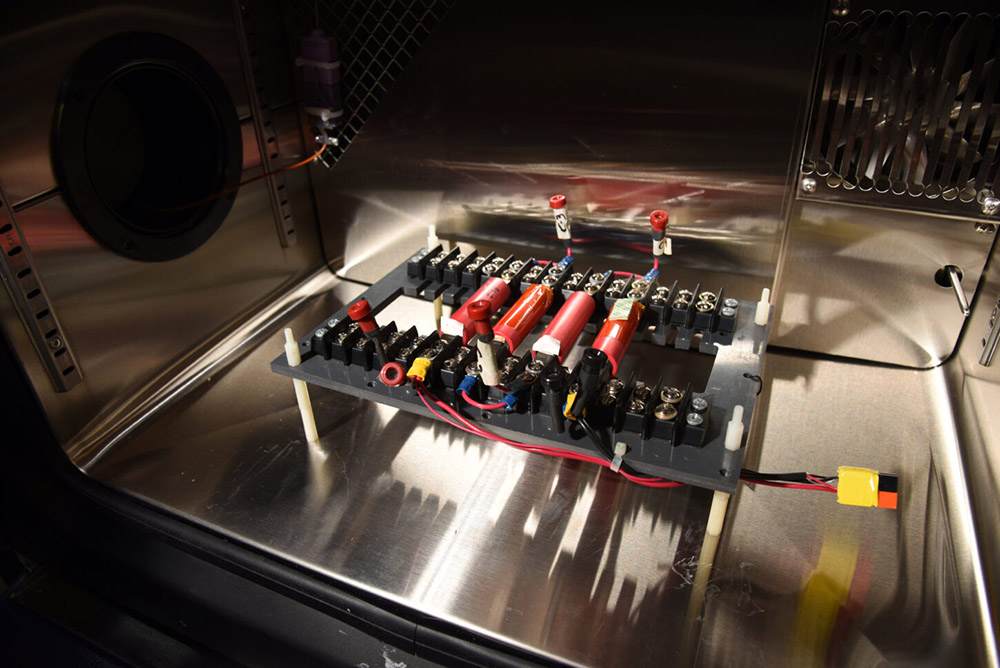

In 2011, Idaho National Laboratory researchers developed a new technology for measuring battery health and safety. By sending multiple waves of electrical current simultaneously through a battery, the Inline Rapid Impedance Spectroscopy (iRIS) technology determines the battery’s resistance, and can monitor how the resistance changes over time. iRIS is faster than other, similar battery diagnostic tools, and can take measurements while the battery is charging or discharging.

Colorado-based Dynexus Technology licensed the iRIS technology in 2015. Now Dynexus has collaborated with Pattern Computer, a company that applies pattern recognition to complex datasets. By combining iRIS with Pattern’s Pattern Discovery Engine, researchers hope to make the tool even more powerful.

Dynexus says battery integrators could use the hybrid iRIS/Pattern technology for difficult diagnostic challenges such as predicting battery failures or matching similar batteries together within the same device so they deliver optimal performance.

Tanvir Tanim, a Senior Battery Research and Development Scientist at INL, uses iRIS during his research, and benchmarks the technology against other diagnostic tools. “It is one of the diagnostics that may be useful to understand battery performance, life and safety early on,” he said. “If you just look at conventional measurements—voltage, temperature and current—it is often difficult to accurately measure a battery’s state of health and state of safety.”

“In order for the reuse and remanufacture of batteries to be sustainable, we need to be able to finance and insure second-use battery assets,” said David Sorum, CEO of Dynexus Technology. “We need to understand the remaining capacity and state of health throughout a battery’s lifecycle. Working together, Dynexus and Pattern can help solve that challenge.”

Source: Idaho National Laboratory