Sponsored by Parker Lord.

The electrification of commercial vehicles, including trucks, buses and fleet vehicles, is gaining significant momentum globally. According to a report by Smart Energy Decisions, there were more than one million electric vehicles (EVs) in commercial and government fleets in the United States as of 2021, up from just over 300,000 in 2019. This represents an increase of more than three times in just two years.

It is projected that, by 2030, there will be more than four million EVs in US fleets. Major factors driving this growth include declining battery costs leading to more affordable EVs, expanded charging infrastructure, government incentives and standards, and corporate sustainability initiatives. Many companies have made commitments to transition portions of their delivery fleets to electric over the next five to 10 years. With major fleet operators on board, the EV fleet market is expected to expand rapidly in the coming decade.

New Emissions Standards for Fleet Vehicles

While the transition to electric fleets may have once been just a trend, it is now a necessity. Medium- and heavy-duty trucks, from delivery vans to tractor-trailers, are major fuel consumers and greenhouse gas (GHG) emitters. To reduce CO2 emissions, many countries signed the 2015 Paris Agreement on climate, pledging to cut their emissions by certain targets. For example, the US agreed to reduce emissions by 26% by 2025, and the EU by at least 40% by 2030.

One of the ways to lower truck emissions is to switch to EVs. According to GreenBiz, the share of electric fleet vehicles is projected to grow from less than 1 percent to 12 percent by 2030, thanks to lower battery costs, industry partnerships and government incentives. Some cities are also promoting the use of EVs for urban delivery trucks, which have shorter ranges and less noise and air pollution than diesel trucks.

In 2023, the Environmental Protection Agency (EPA) proposed new standards to reduce GHG emissions from heavy-duty vehicles for model years 2027-2032, as part of its Clean Trucks Plan. It also proposed multi-pollutant emissions standards for light-duty and medium-duty vehicles for model years 2027 and later. These standards would complement the EPA’s final rule on nitrogen oxides and other criteria pollutant emissions for new heavy-duty engines and vehicles, which was adopted in December 2022.

In recent years, vehicle emission standards have also seen significant advancements, with a marked decrease in CO2 emissions and an increase in fuel economy. The EPA reports that new vehicle CO2 emissions and fuel economy had the biggest annual improvement in the last nine years, reaching record low CO2 emissions and record high fuel economy for model year 2022. With preliminary data suggesting further improvements in model year 2023, this trend is expected to continue in coming years.

Lower Total Cost of Ownership Driving Adoption

The shift toward EVs is also influencing ownership costs. According to McKinsey & Company, the total cost of ownership (TCO) for battery electric vehicles (BEVs) is projected to outperform internal combustion engine (ICE) vehicles across all classes by as soon as 2025. Additional cost-reduction factors include:

- Legislation like the Inflation Reduction Act which offers tax and subsidy incentives, covering up to 30% of vehicle costs.

- Lower fuel and maintenance costs compared to diesel or natural gas vehicles. The cost to charge an electric vehicle is significantly less than purchasing diesel or gasoline.

- Improved range capabilities of new electric truck and bus models, as charging networks expand, making them more practical options for long-haul transport as well.

These trends highlight the ongoing evolution of vehicle emission standards and the economic viability of electric vehicle fleets, signaling a move towards a more sustainable and cost-effective transportation future.

Thermal Management – Key for Performance

Technologies supporting EVs’ needs are key to driving fleet electrification. Challenges that EV OEMs are addressing include limited driving range, battery life and maintenance, to name a few. The newest designs offer fuel savings through lighter vehicle weight by using fewer heavy materials for body parts. Better vehicle shapes also enhance aerodynamics and reducing drag.

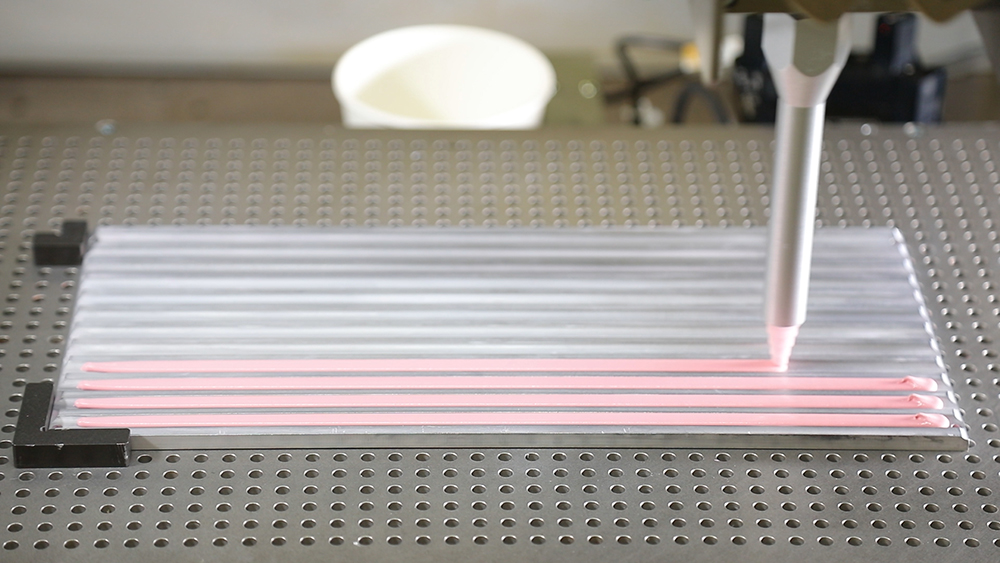

In addition, batteries are evolving to have increased energy density. This increase, however, leads to greater heat output during battery charge and discharge cycles. Improvements in energy density must be matched by improvements in the battery pack assembly. Materials like thermal interface materials, potting compounds, adhesives and coatings enable proper cooling and heat dissipation to maximize power output and battery life. These materials help EVs go longer, charge faster and have greater reliability by managing heat in critical electronic components.

Effective thermal management is critical for optimizing the performance and reliability of high-voltage batteries and power electronics in electric trucks and buses.

Mastering the Heat: Thermal Management Made Easy

As the demand for commercial EV fleets surges, addressing the challenges associated with fleet electrification becomes paramount. A pivotal aspect in addressing these challenges is the use of thermal management materials. These materials play a crucial role in dissipating heat efficiently, thereby safeguarding components from overheating and potential damage. Complementary to thermal management, the application of dielectric coatings has emerged as a vital technique to protect components from electrical arcing, mitigate the risk of fires and enhance reliability in EV charging systems.

Pioneering advancements in thermal management solutions for EVs have led to innovative materials such as Parker Lord’s CoolTherm® portfolio of products that enable their customers to meet their design and performance goals. Thermal management solutions from Parker Lord include CoolTherm potting and encapsulants, thermally conductive gap fillers, thermally conductive adhesives. In addition, Parker Lord offers dielectric coatings to protect EV components from heat and corrosion.

One-stop-shop for EV Fleet Solutions

With a rich history in electrification and a vast portfolio of proven solutions, Parker Lord is a one-stop shop for reliable, efficient and high-performing EV fleet solutions. Their commitment extends beyond products with dedicated technical support from application engineers, ready to assist with product selection, testing and ramp-up. Additionally, they’ve localized R&D efforts in key regions to ensure they understand and address customers’ specific needs.

Overall, the outlook for the future of EV fleets is very positive. According to Statista, EV adoption in the U.S. is projected to grow significantly, with passenger cars expected to reach nearly 44.2 million units by 2030. Globally, the electric passenger vehicle is anticipated to expand to 77 million by 2025, up from an estimated 20 million in mid-year 2022. As the EV market continues to grow, we can expect to see continued growth of EV adoption for businesses’ fleets. This will help to accelerate the transition to a cleaner, more sustainable transportation future.

As the market grows, so does the importance of robust thermal management solutions. Innovations in materials and technologies play a crucial role in advancing the reliability, efficiency and safety of EV fleets. Thanks to their cutting-edge thermal management solutions available today, Parker Lord can work together with their customers to propel the transition toward sustainable and electrified transportation ecosystem. If you have questions, reach out to Parker Lord today.

Want to learn more? Watch Parker Lord’s on-demand webinar “Electrification Solutions for EV Fleets.”