Increasing demand for high power and high-capacity cells are major growth factors for the Li-Ion cylindrical battery market. As such, the demand for battery packs with higher energy output is also growing in sectors such as electric vehicles, industrial power tools, energy storage, consumer electronics, aerospace, defense, and others.

These packs have a need for efficient, dependable, and cost-effective ways to electrically connect the cells to maximize performance, optimize safety, and add value to the end application for the customer. In a typical battery pack module, the cells are organized in an array and then welded together in series and parallel to achieve the desired pack output. The selection of the metal used for this “connection” is not only critical for the overall performance and safety of the battery pack, but also for the efficient manufacturability of the pack.

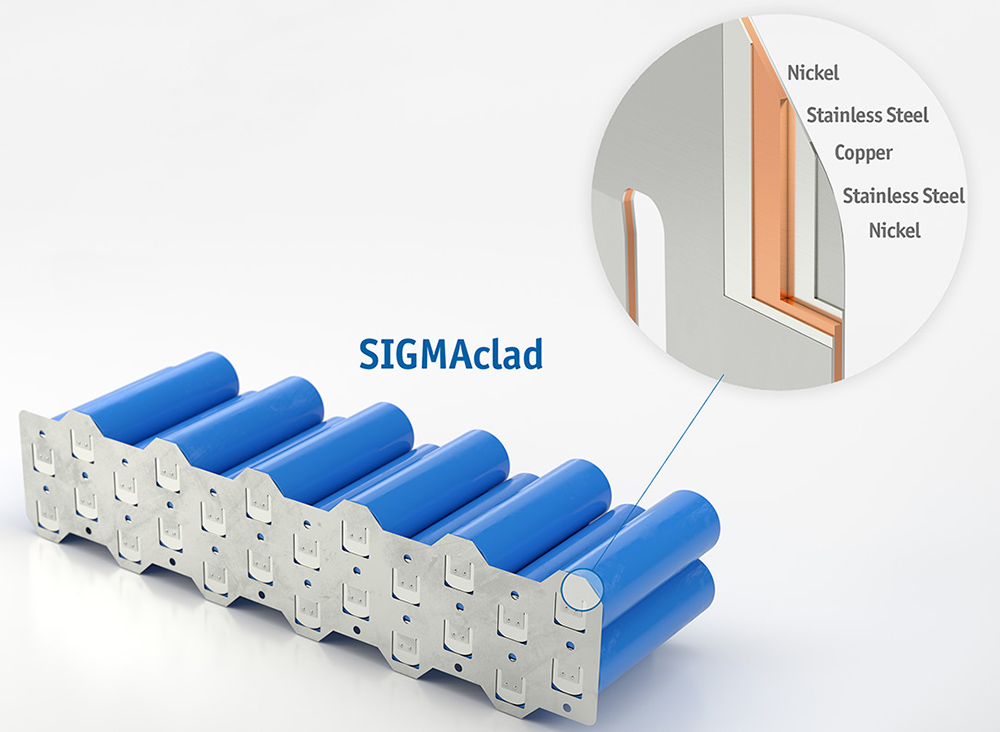

This simple part of a battery pack assembly process is often overlooked. Manufacturers do not realize how they can save production costs and build higher performance into their packs, by making an informed decision on the best material to use. Engineered Materials Solutions designed such a material using our innovative cladding technology that is highly conductive to provide greater thermal and electrical performance while being easily weldable. For detailed information on this novel connector plate material for Li-Ion battery pack assemblies, please click the button below to access the free white paper.