As automakers look to boost EV efficiency, Volkswagen believes bringing development of more components in-house will lead to big gains. VW announced this strategy shift at its Tech Day 2023 event, claiming efficiency improvements of up to 20% by developing its own optimized components.

“The Volkswagen Group and its brands stand for first-class products and technologies,” VW Group CEO Oliver Blume said in a statement. “Thanks to the size and breadth of the group, as well as our in-house expertise, we can leverage economies of scale.”

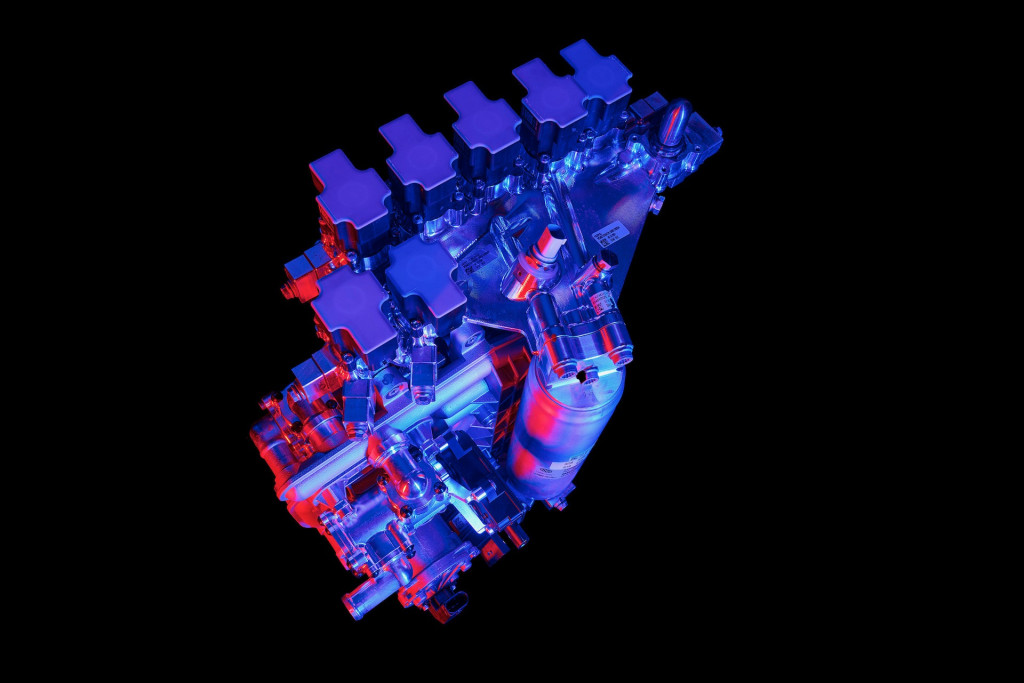

Future Volkswagen thermal management unit developed in-house

VW used to rely on several large suppliers—most notably Bosch—for key powertrain components. But as Tesla has pointed out with its vehicles, there may be some advantage to engineering all done within the company. VW seems ready to try that approach.

Engineers have designed a new pulse inverter and its control software from the ground up, according to a VW press release. The in-house design used the same modular philosophy as the MEB platform developed for VW’s mass-market EVs, and thus with everything from entry-level vehicles to sports cars with an output of 500 kw (670 hp), the automaker claims. It’s currently being refined for series-production use in the next MEB iteration.

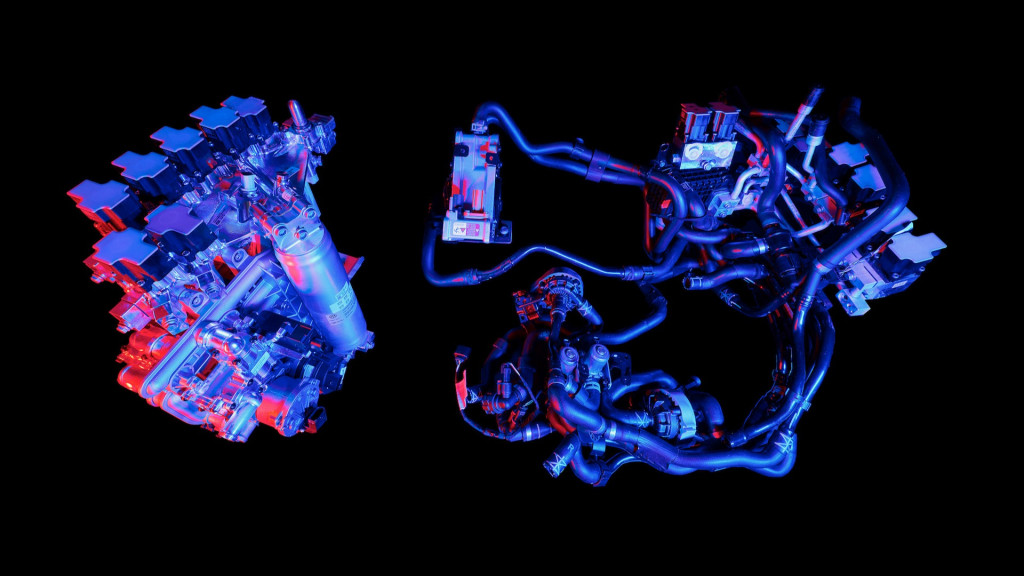

Future (left) and current Volkswagen thermal-management hardware

Another area targeted for in-house optimization is thermal management. In place of the current tangle of individual modules and hoses, the aim is to have an “all-in-one” that can handle temperature control for both the battery pack and cabin. This new module is “significantly lighter, more robust and more efficient” than current versions, and contributes to increased range and more robust fast-charging capability, VW claims.

It’s unclear when these components will reach production, but VW has already teased a mid-decade boost for its MEB platform for affordable EVs. And in the meantime it’s giving MEB vehicles some added range and faster charging.