Researchers develop cobalt-free cathodes using hydrothermal synthesis

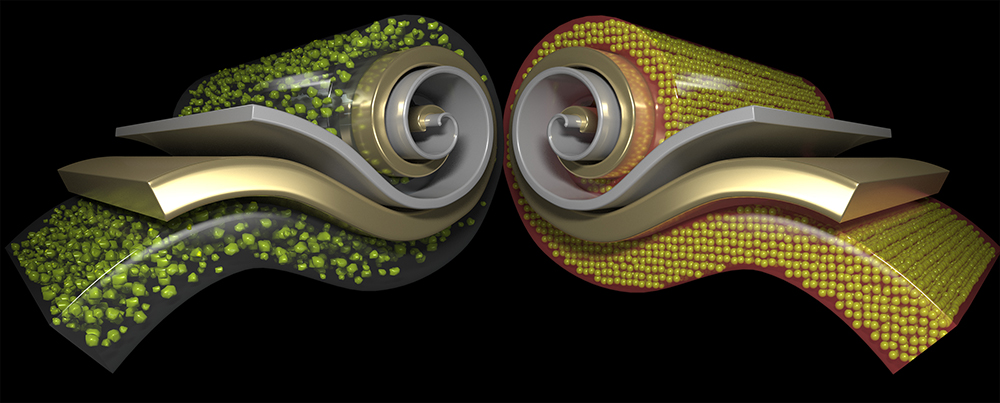

Researchers at the DOE’s Oak Ridge National Laboratory (ORNL) have developed a new method for producing cathodes for lithium-ion batteries by relying on hydrothermal synthesis, which eliminates the need to use cobalt, making the process quicker, less wasteful and less toxic.

They describe their work in: “Hydrothermal synthesis of Co-free NMA cathodes for high-performance Li-ion batteries,” published in the Journal of Power Sources.

Instead of continuously stirring cathode materials with chemicals such as ammonia in a reactor, the hydrothermal synthesis approach crystallizes the cathode using metals dissolved in ethanol, which is safer to store and handle than ammonia and can be distilled and reused afterward.

“This novel process offers the key advantage of moving the cathode industry to cleaner and more cost-competitive production while putting less burden on our environment,” said ORNL’s Ilias Belharouak, the principal investigator for the project.

“The hydrothermal synthesis method is also much faster,” added ORNL lead researcher Rachid Essehli. “The time required to make particles and prepare for the next cathode batch drops from as many as a few days to 12 hours. This cathode material can give more energy and decrease the cost of electric car batteries.”

Source: ORNL