Sponsored by TTI.

Electric vehicles are set to become the basis of future transport, and the transition is happening much more quickly than imagined. In recent months, EV uptake has increased dramatically, with the inflated oil prices currently being experienced likely to accelerate adoption still further.

EV registrations are now getting close to one million per month worldwide. They have already overtaken new diesel vehicle sales (January 2022). Market analysts now expect them to exceed sales for all new internal combustion engine (ICE) vehicles within the 2025 timeframe – far earlier than their previous projections had outlined (where this was not forecast to happen before 2030).

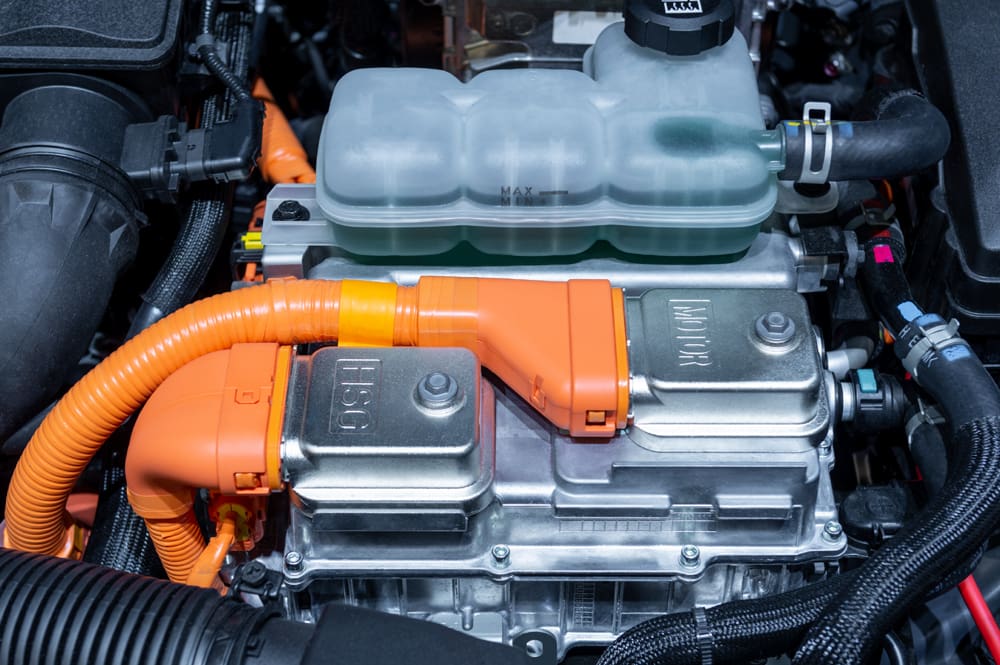

EVs are, in principle, far less complex than traditional ICEs, due to the elimination of the thousands of mechanical components in an engine and all the supporting mechanical subsystems. However, they still present a whole new set of engineering challenges. In particular, more detailed monitoring of key functions and parameters is required to achieve the high performance and efficiency needed to maintain safe operation.

Raising powertrain voltages

Suppose an EV is running at maximum efficiency levels. In that case, the energy stored within the battery will last longer and deliver an extended range, thus the ability to travel a significant distance between recharges. To enhance efficiency and enable shorter recharging periods, automotive manufacturers are increasing the voltages used in EV powertrain architectures from 400V to 800V. Of course, while doing this, it’s critical to maintain vehicle and driver safety.

Ongoing EV battery evolution

Based on Li-Ion chemistry, the battery pack is central to driving the traction motor. However, given the potential for damaged, faulty or ageing cells to overheat, the operating conditions of the pack are continuously monitored at a cellular level. Condition monitoring is done by the battery management system (BMS).

Automotive manufacturers and their battery supply partners are always looking to increase the cell density of their battery packs to deliver greater energy storage capacity from smaller form factors. However, this puts further strain on the cells, so the need for the BMS to be able to access detailed data becomes even more essential.

By using this data, the BMS will not only be able to mitigate the dangers of thermal runaway, but it will also be able to balance the load across all the different cells within a battery pack. Thus, the cells performing poorer than their neighboring ones will not be subjected to harmful stresses. The result is that charge is better distributed across the battery and will last considerably longer, avoiding unwanted replacement costs.

Attributes defining interconnect selection

The safety-critical nature of EV monitoring activity means that data transfer must be carried out at high speed, with low latency and assured reliability. Therefore, connectors that support the data rates defined by the latest in-vehicle networking protocols should be selected. Superior signal integrity also needs to be attained, even with potential sources of electromagnetic interference (EMI) nearby.

Another aspect to be considered is the space-constrained environment. Specified connectors need to be compact, while still featuring a high number of contacts, and be rugged enough to cope with shocks, vibrations, and extreme temperatures.

As the expenses of EVs can often be a concern for prospective vehicle buyers, keeping the overall bill-of-materials costs down is a high priority for automotive manufacturers. Therefore, the connectors must have all the described features and be positioned at acceptable price points.

Interconnects optimized for EV data acquisition

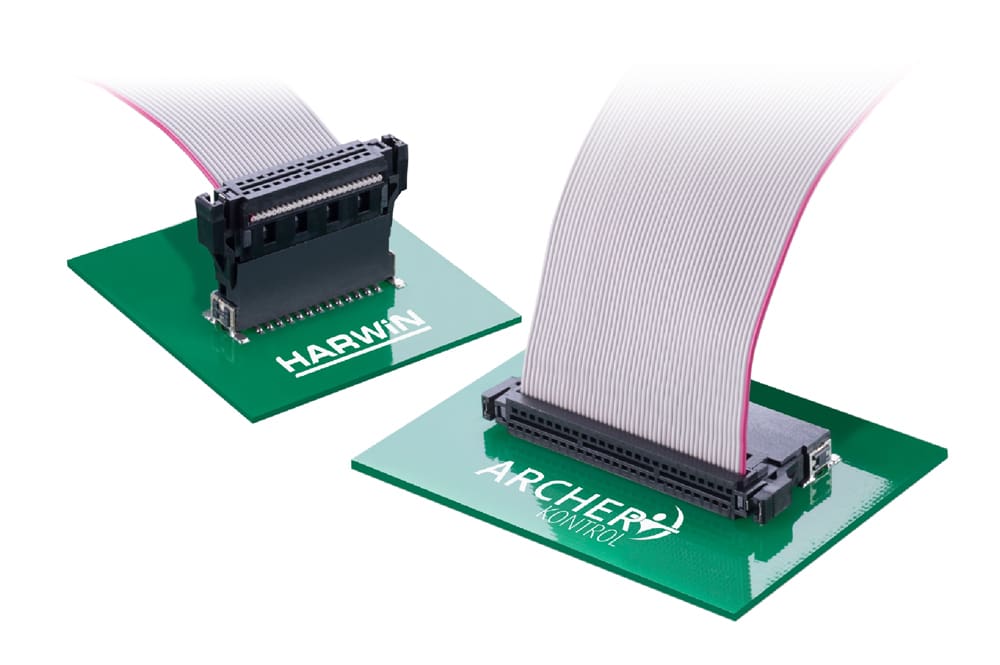

Harwin’s Archer Kontrol board-to-board connectors are used in various EV models for powertrain monitoring and diagnostic tasks. These 1.27mm pitch connectors have compact form factors and can be supplied in vertical or horizontal orientations, so they take up minimal space within the system design. Also, a stacking height from 8mm to 20mm is available, giving manufacturers greater flexibility.

In line with the requirements of automotive applications’ Ethernet network infrastructure, 3Gbps data rates are supported. They can cope with 125°C temperatures, 20G vibrations, and 50G shocks. The phosphor bronze contacts with a gold/tin finish offer prolonged durability. These contacts are embedded into robust plastic housings that have UL94V-0 anti-flammability ratings.

Shrouding the Archer Kontrol connectors protects their contacts from the risk of damage. Available on request are off-the shelf cable assemblies in either 150mm or 300mm lengths, and custom cabling is possible. Latches are included for delivering additional strain relief. In stock and available from TTI.

Future generations of EV powertrains will depend on higher performance data acquisition capabilities. The possibility of real-time communications between all the different powertrain subsystems, from the battery packs to the onboard chargers and DC/DC converters, will result in higher efficiency and greater overall safety. It allows manufacturers to gain a competitive advantage, while safeguarding their brand reputation.