Sponsored by Heraeus Electronics

Lately, the demand for top powered electronics has grown exponentially. With fast progress in electrical/hybrid automobiles, we’re seeing that extra electronics and energy modules are wanted to maintain up with demand. Nonetheless, EV/Hybrid automobiles usually are not the one functions driving this elevated demand. Different main functions, akin to rail traction, wind generators, photovoltaic inverters and motor drives are additionally driving the elevated demand. These functions are extraordinarily demanding and are working at excessive voltage and excessive present densities that should deal with excessive temperatures and harsh circumstances. One of many key elements for a extremely dependable energy module is a particularly dependable steel ceramic substrate. Substrate supplies for these functions should have excellent traits by way of electrical, thermal, insulation, and mechanical efficiency throughout operation. To have a dependable system in place it’s essential to have a suitable interconnection and meeting supplies like solder paste, sinter paste, and wire bonding, to call a number of.

As a result of value effectivity, Al2O3 based mostly steel ceramic substrates, like direct copper bonded substrates are sometimes used for energy module manufacturing. Though, it’s a cheaper answer, it isn’t at all times the most effective for sure functions, particularly for top energy modules. Al2O3 based mostly ceramic substrates battle to harness the total energy of extensive band hole semiconductors. On this occasion, a superior substrate is required. Silicon nitride (Si3N4) based mostly steel ceramic substrates have been used in recent times for energy module meeting. Its superior mechanical properties, akin to bending power, fracture toughness and thermal conductivity makes Si3N4 a gorgeous answer for a extremely dependable, excessive energy density module base. In the present day Si3N4 substrates are manufactured utilizing lively steel brazing (AMB) expertise, which makes use of Ag-filled and titanium containing brazing pastes. Treasured steel and complicated processing steps drive the costs up for AMB substrates making it a costlier choice.

Heraeus Electronics has developed an answer that solves the fee and efficiency roadblocks beforehand described. It’s a value environment friendly, extremely dependable Ag-free AMB copper bonding expertise for becoming a member of nitride-based ceramics with copper foils. The fabric was developed utilizing a method the place there isn’t a requirement for utilizing costly vacuum-based brazing and longer course of time. The product is known as: Condura®.extremely, a Si3N4 Ag free AMB substrate.

Key Options

- Excellent reliability and processing (eg. Sintering, bonding, soldering…)

- Value environment friendly Si3N4 steel ceramic substrate

- Permits thick Cu layers

- Thinner ceramics vs. AIN potential for equal thermal

resistance

- Thermal conductivity of Si3N4 ceramic:

- > 80 W/m∙Okay

- > 60 W/m∙Okay

Condura®.extremely is a cost-efficient Ag free AMB bonding expertise for steel ceramic substrates which can be appropriate for top finish functions. The associated fee discount of Condura®.extremely is achieved by utilizing a silver-free brazing expertise mixed with an environment friendly brazing course of.

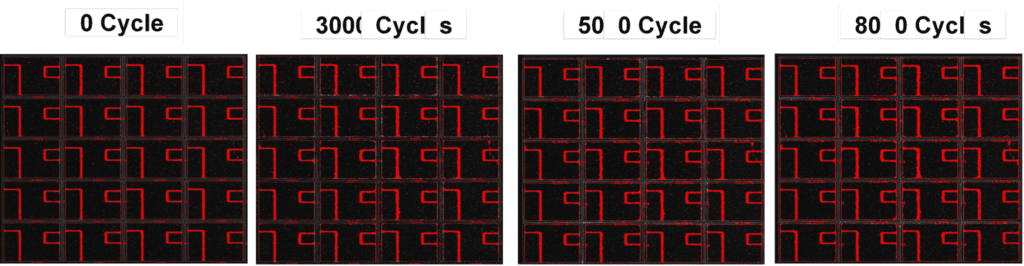

Beneath in Determine 1, it provides a take a look at the thermal shock efficiency of Condura®.extremely.

SAM photos of 20 particular person Condura®.extremely check layouts earlier than and after thermal shock exams (liquid to liquid -65 ° C to + 150 ° C). No main degradation is seen after 8000 cycles. The purple colour signifies the etched isolation groove which is a part of the check format. Within the occasion of delamination between copper and brazed steel as a consequence of thermal shock, the purple colour groove would broaden. This exhibits that Condura®.extremely qualifies to completely leverage the mechanical robustness of the Si3N4 ceramics in the same method because the Ag containing AMB expertise.

Heraeus Electronics displays at PCIM Europe 10-12th Could

Condura®.extremely will launch globally this yr at PCIM Europe. PCIM Europe is the main convention and exhibition for energy electronics, renewable power, and power administration, going down in Nuremberg from Could 10-12, 2022. Whereas on the present go to Heraeus Electronics in Corridor 6, Sales space 322 to talk with our staff about Condura®.extremely or a few of our different new options for interconnects and die connect.

Be part of Heraeus Electronics Dwell on the e-mobility discussion board

On Tuesday Could 10th at 11:20am CEST Heraeus Electronics will provide a sneak peak at our mAgic® Copper Sinter Paste with a presentation titled “ How close to is copper sintering”. For extra data, please go to us on the present or attain out to your native account supervisor.

On Wednesday Could 11th at 12:50pm CEST Heraeus Electronics current on the Condura® product household and the way Heraeus Electronics will meet rising buyer expectations on the reliability, thermal efficiency, lifetime and value of steel ceramic substrates. Additionally on this presentation a brand new addition to the Condura® product line will likely be unveiled.