Sponsored by Bosch Rexroth:

The electrical car (EV) revolution positive factors extra momentum every single day, driving change to automotive manufacturing in unprecedented methods. With quickly rising demand comes the necessity to quickly scale meeting operations — and that may create vital challenges.

Automobile producers continually search new, extra productive automation applied sciences to spice up their high quality and productiveness. Together with many frequent meeting workflows, they face new challenges related to scaling up battery pack and e-axle manufacturing. They want automation options to assist combine electrical battery and powertrain manufacturing seamlessly into total meeting processes.

Bosch Rexroth has an industry-leading portfolio of automation expertise to fulfill these wants, with a long time of expertise offering manufacturing and automation options to main automotive OEMs, in addition to Tier 1 and Tier 2 suppliers.

Broad vary of meeting challenges

Electrical autos have changed engines, fuel tanks and transmissions with electrical motors, regenerative braking expertise and superior battery packs. Assembling these new parts presents distinctive challenges; on the identical time, there are meeting processes frequent to each EV and inside combustion (IC) car meeting strains.

For instance, EVs have physique elements which might be welded utilizing high-speed six-axis robots with superior welding controls. Extraordinarily exact management of weld high quality is important to the long-term efficiency of the car; poor welds can result in separation and vibration in physique elements over time.

To unravel these advanced welding challenges with most velocity and absolute high quality management, Bosch Rexroth has launched the PRC7000 welding controller platform.

The PRC7000 expands the variety of warmth blocks accessible, so plant operations can customise welding to particular throughput and materials traits — a serious benefit over older-generation techniques. Additionally, it will probably retailer as much as 10,000 welding applications that may be simply constructed through a drag-and-drop interface to include extra subtle welding sequences.

Bettering handbook meeting

Although EV vegetation are extremely automated, in addition they use the newest handbook meeting strategies to put in a variety of parts and techniques. Assemblers set up headlights, windshields, retractable sunroofs, seats and door and window controls, typically additionally connecting them to the car’s management module. Precise precision on this course of is important to ship autos that function as flawlessly as attainable.

Bosch Rexroth affords a sophisticated portfolio of clever tightening instruments to supply the productiveness and high quality management wanted for these handbook processes. They supply the exact, repeatable efficiency essential to high-volume meeting strains. The portfolio contains the EXACT ION series of cordless screwdrivers, providing industry-leading accuracy, sturdiness and power effectivity, in addition to ergonomic design and decrease weight to reinforce employee consolation.

Wider use of those sorts of i4.0-ready instruments helps meeting strains improve throughput and function with higher flexibility as completely different car fashions transfer by the road, whereas on the identical time producing important knowledge that plant operators can use to enhance coaching, modify workflows and apply lean manufacturing rules.

A number of applied sciences to spice up battery pack manufacturing

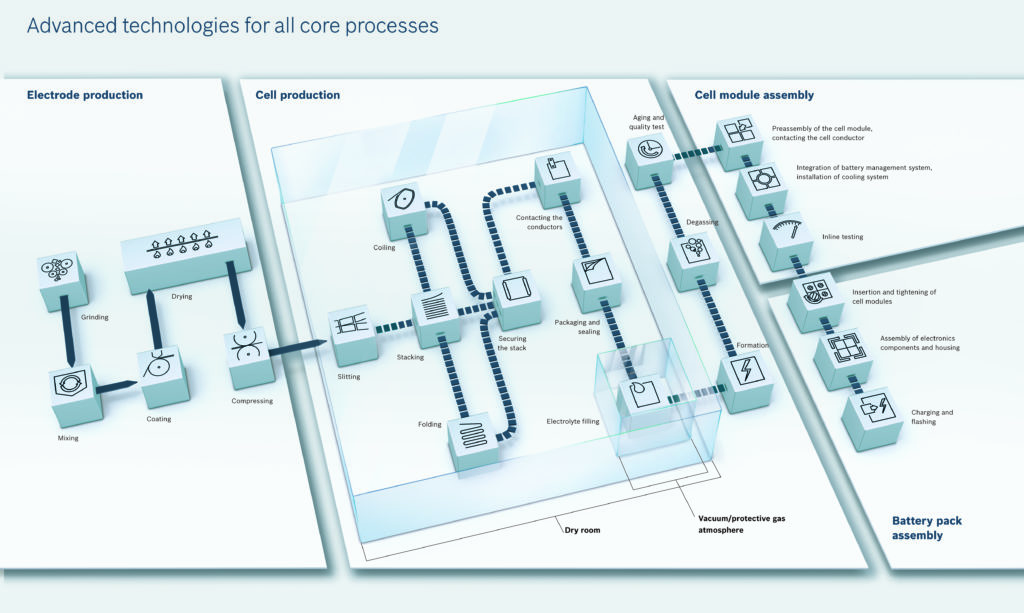

There are 4 main steps in battery pack manufacturing frequent to most operations: electrode manufacturing, cell meeting, module meeting and pack development, which additionally sometimes contains end-of-line battery testing.

Every stage makes use of a fancy array of automation applied sciences to go from uncooked supplies to accomplished packs. Given the important position of the battery within the long-term efficiency and worth of EVs, battery manufacturing requires excessive throughput charges mixed with extraordinarily tight meeting tolerances and high quality management techniques.

In electrode manufacturing, uncooked supplies transfer by a number of automated processing steps. Maximizing management over these processes requires applied sciences that guarantee cells are created with desired electrochemical properties, lifecycle and power density.

Bosch Rexroth’s ctrlX AUTOMATION platform options superior controller and drive techniques designed exactly for these high-throughput manufacturing processes. The ctrlX CORE controller gives superior closed-loop sag and loop management to get rid of breakage and reduce waste. It additionally helps high-speed multi-axis synchronization for internet velocity and place alignment.

In cell manufacturing, particular person batteries — cylindrical, pouch or different format — are mixed into cells. Many producers are working to optimize the stacking course of on this step as a result of streamlining stacking can enhance the throughput of the complete line.

Excessive-speed robotic dealing with techniques, both delta robots or linear robots, are important instruments on this stacking course of. The Smart Function Kit for Handling is a extremely environment friendly linear robotic possibility well-suited to this course of step. It’s really plug-and-produce: fashionable on-line instruments help fast and intuitive part choice and configuration, and the pre-installed software program permits for simpler commissioning, supporting sooner manufacturing begin and serving to velocity to market.

Modular motion and transport options

Going from uncooked supplies to a examined and put in battery pack presents a serious automation transport problem. With every meeting step, weight and part dimension will increase, so a variety of fabric transport conveyors and different techniques is important.

From switch techniques for quickly transferring merchandise weighing just a few grams to linear motor-driven techniques that may exactly transport as much as over 400 kg, state-of-the-art conveyors and linear motor transport techniques maximize environment friendly use of manufacturing facility ground area and allow easily flowing, intelligently linked manufacturing.

VarioFlow plus plastic chain conveyors are confirmed techniques that quickly transfer cell assemblies horizontally, vertically, round obstacles or built-in with different course of flows. These additionally help workpiece pallets to convey cell parts the place positioning or increased stopping precision is required.

Additional down the road, Bosch Rexroth affords the linear motor-based Flexible Transport System (FTS). It helps pallet-based transport and permits for particular person service management for extra advanced motion at sooner throughput charges. Mixed with our intralogistics autonomous mobile robots (AMRs), Bosch Rexroth is uniquely geared up to deal with just about each battery manufacturing transport problem.

Profitable meeting strains design conveyor and materials transport options early within the improvement course of, not as a closing step as soon as all of the manufacturing machines and cells have been outlined. This helps guarantee productive motion of merchandise and supplies by each course of step and prevents constructing in non-value-added transport time. Bosch Rexroth has deep expertise serving to choose and join completely different transport techniques so the best materials move is established — and might be simply modified as manufacturing necessities evolve.

Automation perception to enhance EV meeting productiveness

As EV producers are beneath stress to increase manufacturing, they run dangers by merely throwing expertise at their throughput challenges, moderately than contemplating how nicely their expertise and part selections work collectively. All this meeting expertise needs to be engineered and harmonized to maximise throughput with out sacrificing the standard of the top product.

Bosch Rexroth can leverage its industry-leading automation portfolio and deep automotive manufacturing experience to assist stop this danger. We’ve productive partnerships with main manufacturing facility automation specialists. They work with our skilled automation expertise specialists, following a singular, concurrent engineering strategy.

Utilizing this strategy, we companion to conduct system design, programming and part acquisition and integration in tight, overlapping time frames to deploy full automation options extra quickly.

Our options embody just about each main step in EV manufacturing, with specialised experience in EV battery pack manufacturing. Our concurrent engineering methodology succeeds as a result of we again it, and all our full automation options, with world engineering, service and technical help sources.