LG Chem introduced Tuesday that it’s planning a mammoth cathode materials plant in Tennessee that may help U.S. home electrical car battery manufacturing.

In response to LG, the plant would be the largest of its form within the U.S., and as soon as operating at capability it will likely be in a position to produce 120,000 tons of the cathode battery materials—sufficient to make batteries for 1.2 million EVs yearly, assuming a 310-mile vary per car.

LG Chem stated that the brand new website will plan a key function in quintupling its battery supplies enterprise by 2027, versus 2022 ranges. It is going to additionally assist automakers buying U.S.-made battery cells adjust to pending raw-materials sourcing guidelines within the Inflation Restoration Act. That push to conform has been complemented just lately with a protracted listing of federally funded battery supply-chain projects throughout 12 states.

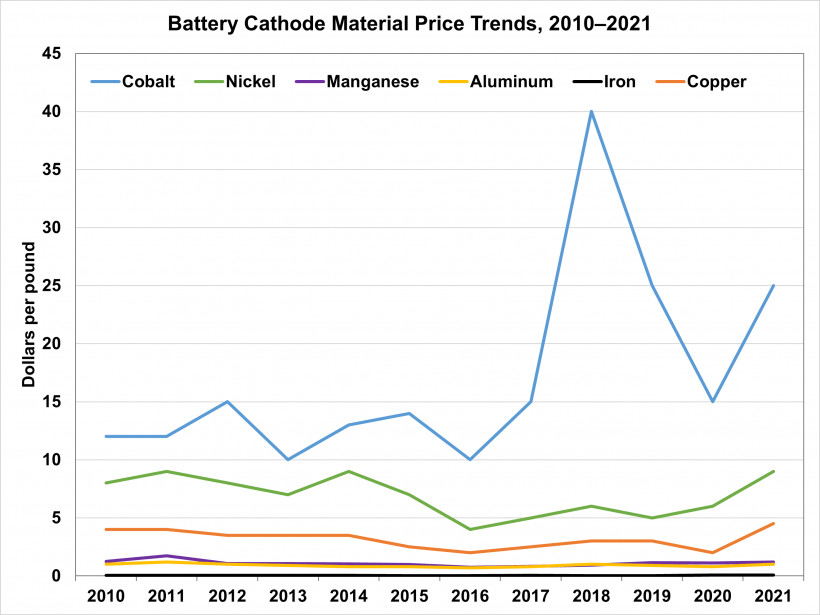

In the meantime, cathode-materials costs have been surging, largely as a result of a heightened demand for them as cell makers ramp up.

EV battery cathode materials worth traits, 2010-2021 – U.S. DOE

Tennessee Governor Invoice Lee on Monday, based on the Tennessean, known as the LG Chem plant the “largest single foreign-direct funding within the state’s historical past.”

The ability will make NCMA (nickel, cobalt, manganese, aluminum) cathode supplies for next-generation batteries which have improved capability and stability, LG Chem says—extending battery capability and EV life. The ability will create greater than 850 jobs, but the corporate stated it plans to automate the whole manufacturing course of whereas establishing “a high quality evaluation and management system that would be the benchmark for all different cathode vegetation on the planet.”

That serves as a reminder that one other LG firm, LG Electronics paid GM $1.9 billion for a battery manufacturing concern that led to the recall of each Chevrolet Bolt EV made, plus widespread battery pack substitute beneath the recall. That concern was attributed to 2 unrelated manufacturing defects that wanted to be current concurrently and, whereas it’s unrelated to the cathode supplies this plant shall be making, it’s a reminder on the significance of high quality management.

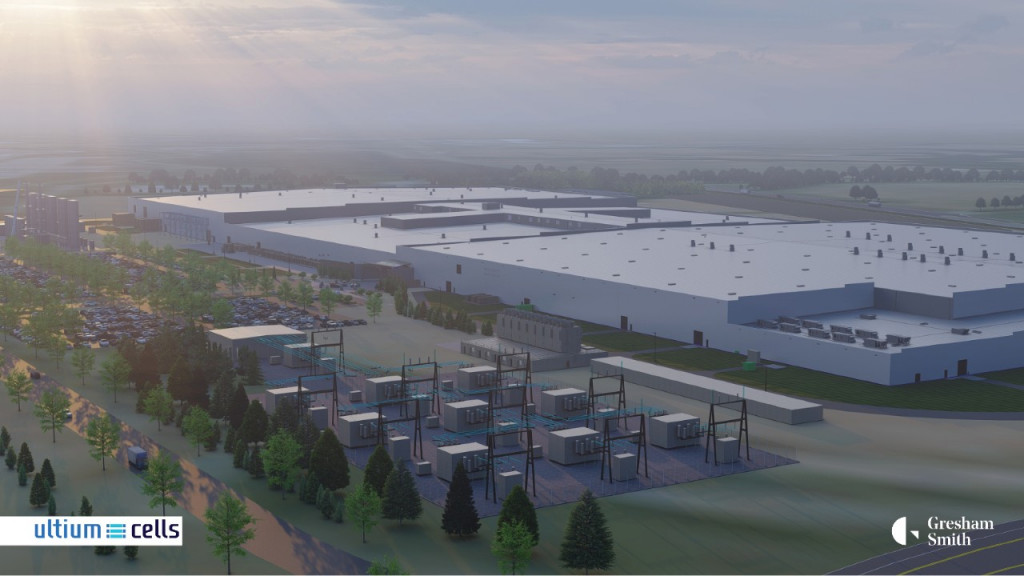

Conceptual drawing of Ultium Cells plant in Tennessee

The corporate didn’t say the place the cathode materials shall be provided to. Basic Motors introduced in July that it has “contractually secured” all battery raw materials to satisfy manufacturing of 1 million North American EVs by 2025, though it’s unclear whether or not that is included in that determine. Ultium Cells LLC joint-venture battery vegetation in Tennessee and Ohio shall be amongst 4 vegetation making cells for GM EVs. In the meantime, Honda and LG Power Resolution have dedicated $4.4 billion to a joint-venture battery plant in Ohio for future Honda EVs, and LG Power Resolution and Stellantis are partnering in a $4.1 billion battery manufacturing plant in Canada.

LG stated that the power will run on 100% renewable power. In response to the Tennessean, the positioning’s entry to Tennessee Valley Authority power performed an essential half within the choice.

The plant will begin mass manufacturing in late 2025, whereas development of the plant is ready to begin within the first quarter of 2023.